Sensor Technology

We

are mainly engaged in the study, development and production of integrated

ceramic pressure sensor, standard voltage and

current signal output module and ceramic pressure transmitter.

We

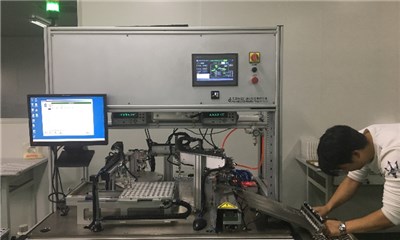

choose ceramic ring produced by Kyocera as our ceramic base, apply thick film resistor printing method,

and use imported laser resistor trimming

machine to do zero adjustment and temperature compensation. Our

self-designed auto-line for temperature drift detection and grading can store

testing data of each product in our server with ID, this enhances traceability

and quality control of our products. We also designed many types of signal amplifying and adjusting circuits,

and designed an auto signal adjusting and calibration software, these

improves our annual packaging and testing capability to 2 million sensors and

0.5 million transmitters. With our precision machining ability to make

different metal transmitter housings, we are able to customize transmitters

with various sizes.

Our

ceramic pressure sensor has many advantages like high sensitivity, low

temperature drift, high stability, high linearity, low creep, anti-corrosion

and easy installation. Its applications cover all areas using pressure control

units, especially in automotive, petro-chemical industries, and electric home

appliance industry.

Our ceramic pressure transmitter has the characteristics of high sensitivity, high accuracy, anti-corrosion, acid and alkali resistant, high linearity, sluggish and longer shelf life. It is used in air compressor, refrigeration machine, central air-conditioning, car engine oil pressure, and water treatment equipment.